Using this Dictionary Instructions

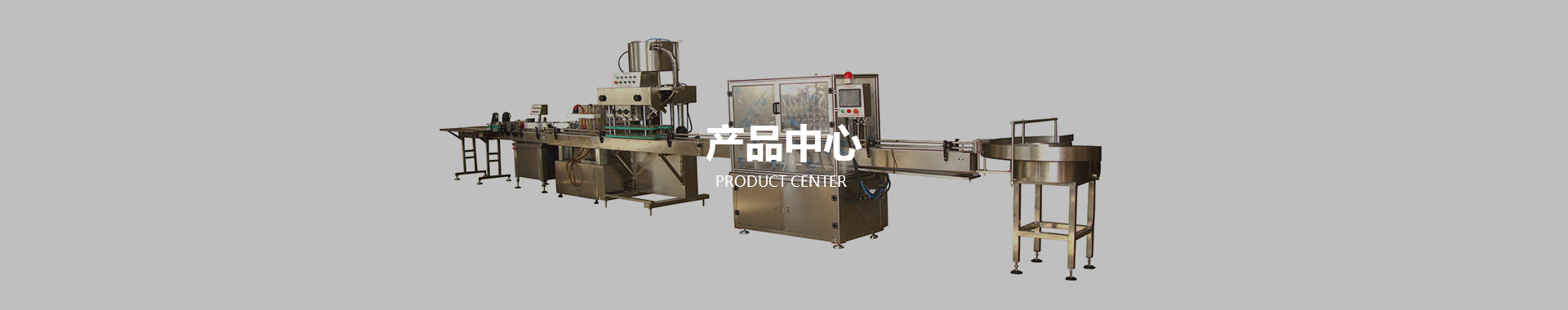

This unit labeling machine is suitable for PET, glass and other

materials 100-500ml round bottle, the highest production speed of up to 10000

bottles / hour. According to the process

and technical requirements of high-speed automatic labeling machine, it is

specially designed and manufactured. The control system adopts advanced

programmable controller to control; high performance stepper motor with advanced

driven method to drive ; various state and parameter display clear.

This adhesive

labeling machine manufacturing structure is simple and reasonable. The utility

model can automatically paste the self-adhesive label paper on the bottle body.

In case of bottle missing, the control system of the machine can ensure that

the label paper is not sent out, effectively prevented waste the labels, and

the production capacity can be continuously adjusted according to the

specifications and characteristics of the bottle and the labeling paper. Mainly

used for the surface labeling of all kinds of round bottle, the bottle on the

surface of the self-adhesive label paper paste labeling process smooth and

beautiful appearance, stable and reliable, the marking position fully meet the

ideal requirements for modern machinery for labeling.

advantage

1, fast running

speed and stability, high accuracy.

2, the

carrier labeling process will not be damaged, the labeling effect is good,

smooth, wrinkle free.

3, simple operation,

automatic feeding, labeling, receiving, lacking of label detection and automatic

electric eye pause function.

Working Principles Working principle

The

beginning of the process is that the bottle is fed to the labeling machine at a

constant speed on the conveyor belt. A mechanical fixing device separates a

fixed distance between the bottles and pushes the bottle along the direction of

the conveyor belt; the mechanical system of the labeling machine includes a

drive wheel, a labeling wheel, and a reel. The driving wheel intermittently

drags the label belt movement, the label belt is pulled out of the reel, and

the label wheel is pressed on the box by the labeling wheel. An open loop

displacement control is used on the scroll to maintain the tension of the label

band, since the labels are closely connected with each other on the label band,

so the label belt must continuously stop and move on.